Put your brand figuratively in your consumers’ hands. For businesses, custom-branded packaging is a potent and affordable marketing tool. You may increase brand recognition and set your business apart from the competition by using custom-branded

packaging.

Utilize the chance to expand and improve your company by customising an Ecoware product when minimum purchase quantities are met.

We make every effort to make the procedure as smooth and straightforward as we can. As part of your custom branded packaging, we provide the following services in order to achieve this.

Our creative team will create and build your custom-branded product.

Only a one-time fee for putting up your print plates, which are utilised to print your design on our product.

In order to guarantee that we deliver the most effective and efficient freight services possible, we decide to store your merchandise in our warehouse when it is required.

To best fit your business, we provide a variety of payment options; we will adjust as necessary.

And last but not least, we offer a full stock management service to make sure you never run out of your custom-branded packaging.

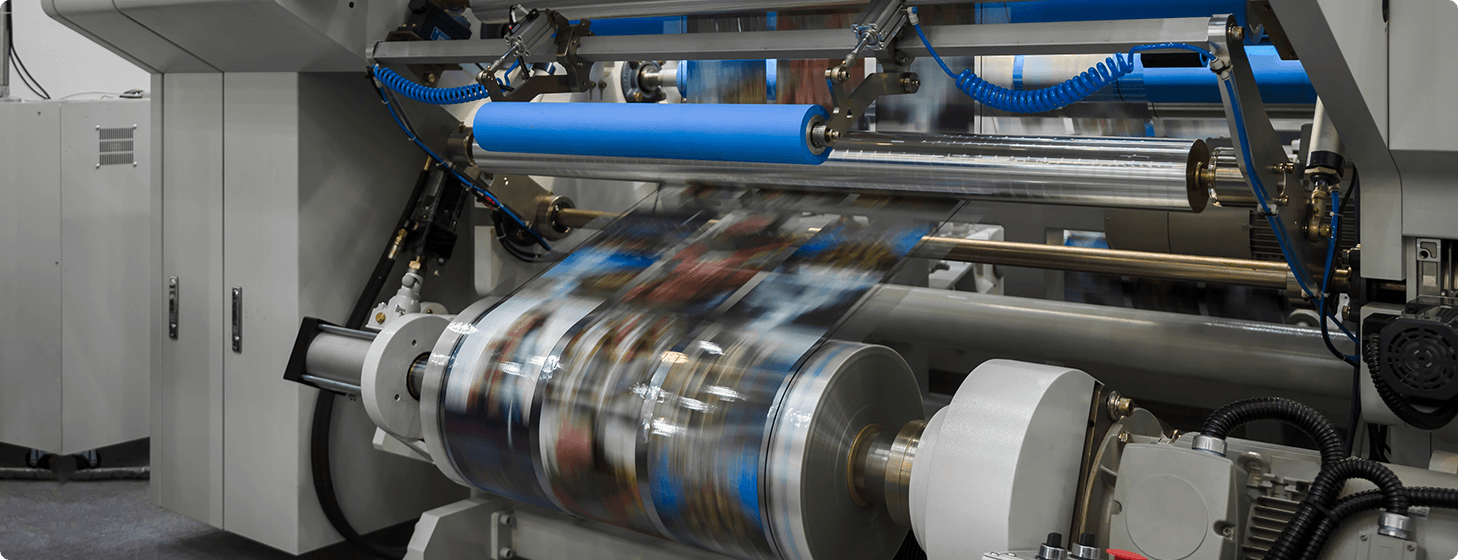

Depending on order amounts, we employ one of two printing techniques when we work with you to personalise your packaging requirements. Here is a brief explanation of the printing techniques we employ at our production facilities:

Off-set printing, referred to as off-set lithography is one of the most common methods of printing in today’s modern age. This printing method is used on production runs in excess of 50,000 units, where we are required to print a detailed image using a large number of colours. Each unit is individually printed one by one using thin and flexible aluminium plates.

Flexo printing, referred to as Flexography printing, is used for the majority of our production orders and uses Pantone spot colour. As opposed to printing each individual unit one by one, Flexo printing uses a flexible relief plate that enables a continuous production line and will print the full job without stopping

| Product | MOQ | Lead Time |

|---|---|---|

| Hot Paper Cup | 30,000 pcs | 12-16 weeks |

| Kraft Cup Sleeve | 10,000 pcs | 5-7 weeks |

| Cup Carrier | 50,000 pcs | 8-10 weeks |

| CPLA Cutlery | 10,000 pcs | 7-9 weeks |

| CPLA Straw | 10,000 pcs | 7-9 weeks |

| Clear Bowl | 20,000 pcs | 4-9 weeks |

| Clear Cup | 20,000 pcs | 4-9 weeks |

| Paper Bowl | 30,000 pcs | 8-10 weeks |

| Napkin | 10,000 pcs | 6-8 weeks |

| Kraft Tableware | 30,000 pcs | 8-9 weeks |

| Kraft Handle Bag | 30,000 pcs | 5-7 weeks |

| Wet Wipes | 10,000 pcs | 8-10 weeks |

| Paper Salad Bowl | 50,000 pcs | 8-10 weeks |

| Paper Soup Bowl | 50,000 pcs | 7-9 weeks |

| Paper Soup Tub | 50,000 pcs | 8-10 weeks |

| Ice Cream Cup | 10,000 pcs | 8-10 weeks |

| Ice Cream Spoon | 50,000 pcs | 8-10 weeks |

| Fast Food Packaging | 10,000 pcs | 8-10 weeks |

| Sugarcane/Bamboo Tableware | 10,000 pcs | 4-10 weeks |

| T Shirt/Fruit Bags & Bin Liners | 20,000 pcs | 5-8 weeks |

Our professional design team will collaborate closely with you to create and build your own own customised items. Sending us your logos and brand standards is all we ask; we’ll take care of the rest. Here are some examples that we use to make your packaging come to life:

(1).png)